I got this nice MGF enhancement from my dear wife for my 48th birthday

The above car doesn't exist any longer. I unfortunately crunched the car six month later, but survived the roll over accident non-hurt

|

how it arrived directly from Taiwan

|

Kit package No. 2. All parts secure packed in foam bags

|

multifunction

alloy main frame, individual marked with a serial Number

|

The first try :) it waits on getting assembled |

|

off

the T-Bar

One of two clips got broken, Oh, its an MG :) ... or my poor craftmans skills, who knows ... |

A load of stainless steel bolts, washers, nylock nuts and studs :) |

a node to the seatbelt and off the bolt with a Torx 50 driver | bracket at the seatbelt runway. The Jigsaw will cut you soon :)))) |

|

loosening the belt at the seat, a really boring job.... You need a T50 wrench |

Loosen the doofers bolts and take care of the rear fixture plate | directing

the screw driver to the T-Bars center hole & the screw to the main

frame |

Right hand and left hand sides gap of the T-Bar to the door sealing. Everything was OK and much easier as it looks here. |

|

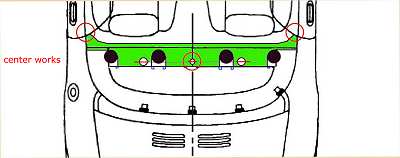

centering the

T-Bar to the door seals, The following works to the T-Bar took a long time of cutting, but I enjoyed it :)) |

|||

| template sticker, secure is secure, better check double and triple before anything goes wrong at the later cutting of U-shapes | preparing the template sticker, for pasting it to the T-Bar. At first bend it sharp at the position of the center hole and then only cut the cover paper on the bottom side. | The pasted sticker. The ends at the right and left side shape are a bit long, but indicate to cut parallel along the rear edge of the T-Bar | shape depth parallel to the rear edge, here indicated by the red marks |

| A

M4 long threaded bolt screwed to the mainframes centre hole is vital

to direct the cut works in a closed loop by cut, check, cut. ... works like building a sculpture. :o) |

the top view indicates on each interference | ||

| shapes seen from out of the cars inner side | 2mm gap between the mainframe and the T-Bar foam should be ... but who cares, I am a 'small mashine engineer' and count in 1/10th mm... *g* | ||

| 90 percent ready, hoops to bolt on from below, carpet to cut, windstop hinges to assemble | final carpet cut works | ||

|

With

hoops only, at the river 'Aller' north of Hannover

|

special

minds go to this hill at my birthplace. :) My father worked here 20

years ago and I often brought him his lunch

|

||

|

three

month later I unfortunately had a strong roll over accident. Survived

non-hurt.

|

|||

|

|

|||

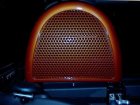

| This

is another installation of our omnibus purchase. Customised windmesh, complete sprayed in volcano orange Sorry, the weather here is currently only good for garage photos |

|||

|

*g* I'm not that chrome shine lover, .. pssst....so lets see how to

customise the windmesh to my individual requirements. May be I'll let

it spray in BRG with PU-paint to match my MGFs colour, but only the

outer chrome shining bow, not the black mesh in my case. :)) |

I needed about

6 hours including the photos for completing the works.. |

Now I customised the shining mesh frame to anthracite colour. :)) |

The hinges got sprayed in black colour. |

| ARTRA No 92 installed in May 2001 at Nikolaijs MGF. | |||

|

The German TÜV

authority released this job in individual case. all other availiable stuff is not designed with CAD and for my knowledge not calculated by 'finite elements' |

Material no longer

available: The Original Part

Design from ARTRA and Don Liang has no relation to other similar part

!! |

||